BHO stands for butane hash oil. It is a solvent-based cannabis extract that uses butane to remove the active compounds from cannabis flowers. The butane is then purged from the extract using heat, leaving behind a potent, sticky concentrate that can take on a variety of consistencies depending on variations in the extraction/post-extraction process.

While BHO might seem like the new kid on the block, its roots actually lie in some pretty old-school extraction processes. The idea of extracting and concentrating cannabis compounds is far from new; in fact, hash-making dates back centuries in places like Morocco, India, Nepal, and Pakistan (where hash, or charas, played an important role in spiritual ceremonies). In fact, even in the US, cannabis extractions and tinctures lined the shelves of pharmacies up until the early 1900’s.

Solvent-based cannabis extractions even found their way into the US military post-prohibition. Confirmed and declassified WWII intelligence documents tell the tale of the US government and military using cannabis acetate and LSD in its interrogations.

While they might seem relatively detached from the extremely potent and aromatic BHO sold at US dispensaries, these historical footnotes helped lay the foundation for the processes used to make modern concentrates. And while it’s hard to pinpoint the exact date BHO was created, we do know that the principles used to make it stem from the traditional extraction methods used to make tinctures, hash, and charas.

BHO differs from other cannabis concentrates in a number of ways. First of all, it uses a solvent to extract the active chemicals from cannabis flowers. This is different from traditional hash or charas, which are both made without the use of a solvent (hash is made by using fine sieves to separate trichomes from dried cannabis buds, whereas charas is made using friction and heat to remove trichomes from live cannabis flowers).

Second, BHO differs greatly from other solvent-based extractions, such as tinctures (which are typically made with alcohol), both in its manufacturing and in its texture, flavour/aroma, and potency.

Unlike some cannabis concentrates, BHO is very sticky, has a distinct golden appearance, boasts very unique aromas that can’t be compared to that of regular hash, and is extremely potent. Some BHO extracts sold at US dispensaries can reach THC concentrations of up to 90%.

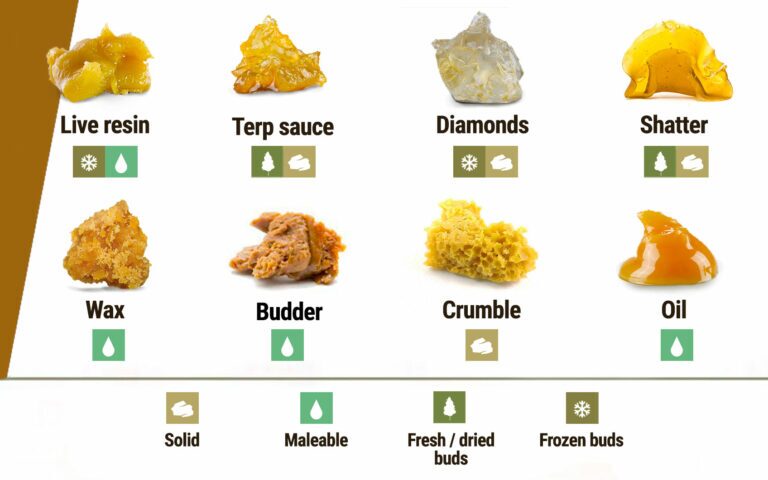

Oil, sauce, wax, budder—BHO is sold under a variety of different names. Below we’ll shine a light on the different types, and see what makes them unique.

Live resin is a really unique form of BHO because it is made using freshly harvested and snap-frozen cannabis buds, not the dried and cured buds used to make other types of BHO. It typically has a rich, golden-to-dark-yellow colour and a malleable texture. Its aromas and flavours are notably richer and more delicate than those of other types of BHO.

The act of using freshly harvested buds lends live resin a really unique profile. That’s because this process helps preserve terpenes, many of which are extremely sensitive to higher temperatures and are lost during drying, curing, as well as traditional extraction processes (which use heat).

The origins of live resin date back to roughly 2011, when a small group of professional cannabis extractors from Colorado developed a specialised BHO extractor that could maintain extremely cool temperatures throughout the extraction process.

Terp sauce has rapidly climbed the popularity ladder, and is probably one of the most sought-after forms of BHO currently on the market. It has a very unique texture, similar to crystallised honey, and offers a very distinct aroma, flavour, and effects profile compared to other forms of BHO.

In some ways, terp sauce is similar to live resin in that it boasts richer aromas and flavours. When it comes to its production, however, terp sauce is made using processes similar to that of BHO diamonds (more info below).

Terp sauce can be made using fresh or dried buds, and starts with a regular butane extraction. The mixture is then purged at low temperatures and allowed to sit for 2–3 weeks, allowing more butane to purge from the mixture and the terpenes and cannabinoids to start separating. After a final purge, the sauce is ready to go, forming a thick, crystalline texture and boasting amazing potency and aroma.

Diamonds are the latest craze in the world of cannabis concentrates. And while they’re hard to get one’s hands on, and, as a result, very expensive, weed diamonds will blow your mind. Literally; these tiny crystals of pure, isolated cannabinoids boast a potency that is difficult to top.

Weed “diamond mining” starts off just like regular live resin extraction; by dousing freshly harvested, snap-frozen cannabis flowers in sub-critical BHO. The resulting resin is then purged at roughly 32°C before being left to separate for 2–3 weeks. During this process, the cannabinoids will separate from the terpenes and form crystals at the bottom of the container while the terpenes form a thick, semi-viscous layer on top.

Once separated, the diamonds need to be purged one final time to remove any residual butane. The resulting diamonds quite literally look like perfect little gems and boast massive purity (nearing 100%), while the terpene sauce can contain anywhere from 30–50% cannabinoids.

Shatter is one of the most easily recognised forms of BHO. This brittle, glass-like concentrate is extremely popular in legal markets, and it’s not hard to see why. It boasts high potency as well as great flavours and aromas, at a more affordable price than some of the other, more complex forms of BHO mentioned here.

Shatter gets its unique texture from its manufacturing process. Once liquid butane has been doused over the dried flowers, it is collected and allowed to form a thin layer on flat trays. The butane is then gently purged from the mixture at low temperatures to avoid combustion. Following the purge, the extract is allowed to cool and settle, a process during which any remaining butane continues to evaporate.

The finished product has a thin, brittle, glass-like texture and can boast cannabinoid concentrations of anywhere over 50%, sometimes even crossing the 90% mark.

As the name suggests, BHO wax has a thick, waxy texture. Not solid enough to be shatter, yet not liquid enough to be considered sauce or oil, wax is sticky, tasty, and ultra-potent. It usually has THC concentrations of 50–90% and is another favourite at many US dispensaries.

Wax isn’t completely translucent. Instead, it has an opaque, golden appearance similar to beeswax or honey. It gets its unique texture from its purging process. Unlike shatter, which is left to rest and purge undisturbed, BHO wax is agitated lightly during the purging process. Not only does this allow for a faster purge, but the subtle agitation is also one of the main contributors to wax’s unique texture.

If you’re lucky enough to get your hands on some BHO wax, make sure to handle it carefully, preferably using a dab tool. This stuff is super sticky and known to make a huge mess if not handled swiftly when loading it into your rig.

BHO budder is rich, creamy, and mouth-wateringly delicious. Like wax, budder is agitated during the purging process, which is what gives it its uniquely thick texture, similar to real butter.

While the exact techniques used to make BHO budder can obviously vary from one extraction lab to another, the basic principle behind creating this unique extract is simple. By heavily agitating the BHO as it purges, the mixture starts to take on a thick, creamy texture and opaque appearance. Its colour can vary, but budder tends to be a light-to-medium golden colour and boasts THC levels of anywhere up to 80%.

BHO crumble can vary pretty dramatically in texture and appearance. If you’re lucky enough to visit a legal cannabis market where there’s a wide variety of BHO on sale, you might be particularly surprised to see the difference between batches of crumble.

One of the key characteristics that sets crumble apart from other types of BHO is its dryness. Some types of crumble can be so dry that they almost resemble grains of sugar or clumps of honeycomb. Other crumble can be slightly wetter, but this is, in general, a very dry type of BHO.

Crumble owes its unique texture to an equally unique purging process; during the final stages, crumble is loaded onto a pan, placed inside a vacuum oven, and purged at relatively low temperatures (much lower than those used to purge other types of BHO). This low and slow purging process is what gives crumble its unique dryness.

BHO oil is the most loose form of BHO, although the exact consistency can vary from one producer, and batch, to another. Thicker and less-viscous oils are often sold as sap, due to their similar consistency to tree sap.

Because they are so hard to handle and load into a dab rig or vape, oils have become far less popular over recent years. Instead of being vaped or smoked straight-up, they are often used in twaxing or the creation of moon rocks.

Yield

From frosty trim, you should be able to get at LEAST 10% yield. Meaning… if you start with 100g of product, you should get at least 10g of shatter. From bud, I have got up to 22-23% yield, but normally the yield on bud is around 16-20% (depending on the quality). With some less frosty strains, yields will be around 12-15%.

Preparing your material

If you’re going to blast bud: whether it be lower airy buds, or premium tops, you’ll want to dry it and cure it the same way you would if you were making bud to smoke. A day or two before blasting, take your buds and chop them up with scissors so no bud is bigger than a marble (you can also do this while you’re trimming). Then I let the material dry a little further, to about 50% humidity, before blasting. We don’t want any moisture in the buds, but we don’t want them so crispy that they turn to dust when you handle them. If you attempt to blast before your material is fully dry, your shatter may have a green tint to it.

If you’re going to blast trim: Then you’ll need to think ahead while you’re trimming. Throw fan leaves in the garbage, and cut all the frosty trim into a bin. You’ll have some small fan leaves with a little frost on them. It’s up to you if you want to throw these away or blast them. The more “non-frosty” leaves you put in the tube, the lesser quality and lesser yield you will get.

Filling the tube

Start by packing a reasonable amount lightly with a glass/wooden rod or something similar. The material should be packed in so there is no air pockets, but not too tight as this will decrease yield. You’ll have to experiment to see what works best for your tube.

Now attach two coffee filters to the open end of the tube and secure it in place, it is important that any fittings are tight as pressure will build up inside the tube, and you don’t want leaks or blow outs.

Once it’s full, place it in the freezer for 24hrs.

Pre-heat your vacuum oven to 30C

Setup and Blasting

Once everything is frozen, you’ll need to begin setting up a spot outdoors with plenty of open air and ventilation around you.

In this area you will need:-

Take the larger Pyrex dish and place enough water (at ~30-40C) to allow the second dish to float on top without it touching the bottom, make sure you take account of the weight of the butane too. In the second dish you would have placed the silicon paper/PTFE inside of the bowl, this will stop the material sticking to the Pyrex and going to waste. It also makes future stages much easier/quicker to complete.

Remove the tube from the freezer and wrap the towel around it, making sure that you keep it away from either end of the glass. When frozen and then exposed to warmer temperatures, it may end up sweating moisture, which could fall into your tray and ruin your extract. This will make it turn out much softer than expected.

Retrieve the gas from the freezer – place the tube vertically above the tray and empty your gas into the injection hole at the top of the glass. As the gas begins to descend through the tube, it brings any cannabinoids with it and you will begin to see it flow out the bottom into the tray.

Removing excess Butane

In order to get rid of the most gas possible from the extract, you will need to let the mixture sit in a bed of warm water. You will notice the Butane/oil mix boiling off, this is because Butane boils at room temperature, perfect for what we need. Try and keep the broiler temperature between 30-40C as otherwise there is a good chance you will cook off the terpenes that we are trying to keep!

DO NOT STIR!! Do not pop bubbles, do not swirl your oil around, move it as little as possible. Any stirring and your shatter will not look clear at the end, and it will be more difficult to purge all the butane out of the oil.

If you see some goop floating in your BHO material, don’t panic. This is frozen moisture that was pulled out of your plant material or introduced via moisture from the tube. You can scoop it out with a fork, or leave it. If left, you may risk trapping some moisture into the shatter, which will make it snap/crackle when heated. Most of the moisture will more that likely evaporate out in the vac/purge process anyway, so unless it is excessive you may be better off leaving it for the vacuum purge to deal with.

Once you’re sure that there are no visible traces of gas, make sure by checking if it has a treacle like consistency, which is a good sign the initial boil off is complete.

Vacuum purging

Remove the PTFE/Silicon paper with the extract from the dish and place it into the preheated vacuum oven.

Lots can go wrong here, so pay attention. Your chamber should have a valve between the chamber and the vac as well as another to let air INTO the chamber. You will use the air valve to control the pressure in the vac. and the pump valve to hold the pressure in the vac when the pump is off.

CAUTION, if the vac is under pressure and you turn off the pump with the pump valve open, your chamber will suck air from the pump line, and could pull in lubrication from the pump and completely ruin your shatter.

Turn on the pump and watch the oil, pretty quickly the vacuum will cause the oil to balloon out. You need to make this as big as possible without it touching the sides of the chamber. If it does touch, you won’t be able to get it off very easily. YOU HAVE BEEN WARNED!!

By making it balloon out, we are expanding the oil and allowing air to evaporate the gas more efficiently from the oil. The size can be controlled using the air valve, so make the use of any space available in the oven.

Keep the vac on for about 15 to 20 minutes, or until the balloon drops in size. The better quality oil you have, and the more vac you have, the longer the balloon will stay puffed up. Usually it will stop expanding after about 15 minutes and then you can fully close the air valve and take it to full vac. A more expensive pump doesn’t achieve a higher vac, but it gets there faster.

After an hour, your muffin will deflate and start to look like this:-

In a few hours it should look iike this:-